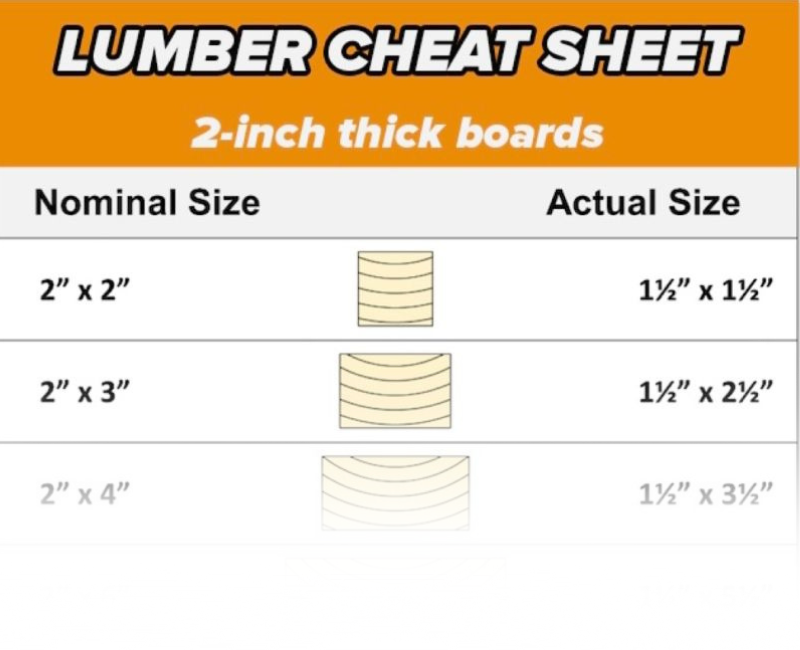

In our previous post about Mastering Lumber, we walked through the important difference between nominal and actual sized lumber. Once you know the size of lumber you need, the next step is figuring out which boards to choose for your project. Below are 5 quick points to consider when choosing lumber. Plus, we included another lumber cheat sheet at the bottom...

1. What should the board look like?

Although it may sound obvious, it's essential to make sure you choose a straight board. Always double-check to make sure the board is not cupped or bowed. You can even do the trusty nose trick with the board to check it isn't warped by lining the end of the board up with your nose and looking down its length on all four sides. Always check and recheck your boards before purchasing them. We promise it isn't fun trying to cut bowed lumber.

2. What defects do I worry about?

When choosing lumber, you'll run into many different types of wood defects in lumber, so we'll just touch on a few common ones.

First, knots. These are one of the most common, naturally occurring defects. A knot is usually only a visual defect and doesn't normally compromise the wood structure.

Checks are cracks that occur along the growth rings of the wood. Small checks shouldn't be a significant issue, but large, deep ones can weaken the board and affect its structural integrity.

Splits are similar to checks but occur across the board's width. Like checks, small splits should not be a major concern, but large ones can make the board unsuitable for some applications.

Warping includes cupping, bowing, and twisting of the board. As mentioned earlier, any boards that are not straight can cause problems during cutting and assembly, and can even be dangerous!

Wane refers to the presence of bark or the rounded edge of the tree on the board. While a small amount of wane may not be an issue, excessive wane can reduce the usable area of the board.

Unusual grain patterns or interlocked grain in the wood can make it more challenging to work with and may lead to tear-out during planing or sanding. Always keep in mind that the grain is visible through most stains, and will give your work a "personality" (more on this later).

3. How do I translate this stamp?

When buying lumber, you may come across a stamp or grade mark on the boards. This stamp provides valuable information about the lumber's quality and characteristics. Each country might have different grading systems, but here's a general idea of what you might encounter on the stamp:

Species: The type of wood species is usually mentioned on the stamp. It's essential to know what type of wood you're working with, as different species have varying hardness, grain patterns, and other characteristics.

Grade: The grade indicates the quality of the lumber. Common grades include Select, #1 Common, #2 Common, and #3 Common. Higher-grade lumber will have fewer defects and a more uniform appearance, making it suitable for projects where aesthetics are important.

Moisture Content: The stamp may also provide information about the moisture content of the wood. Keep in mind that wood with a high moisture content may shrink or warp after purchase if not properly dried.

Certification: Some stamps might indicate that the wood is certified by a specific organization, like the Forest Stewardship Council (FSC). This certification ensures that the wood comes from responsibly managed forests.

Understanding these stamps can help you make informed decisions when choosing lumber for your woodworking projects. If you're unsure about any of the information on the stamp, don't hesitate to ask the lumberyard staff or a woodworking expert for clarification.

4. Do I worry about the grain?

The choice ultimately depends on your project. If you're staining, the grain will be more noticeable, but if you're painting, it will be less noticeable. If you're staining multiple boards and want them to be consistent, try to choose boards with similar grain patterns.

5. Wait... What's that price for?

Always check how a board is priced. Although most lumber is priced by the board foot, some can be priced per board, so it is important to always double-check the tag. And don't forget to make sure you have the correct sized board you need. If you're confused by the nominal vs. actual sized lumber, download our 2-inch Lumber Cheat Sheet for a quick reference, and check out our previous blog post.

Interested in milling your own lumber? Check out our previous blog post on it here.