Woodworking is a craft as old as time yet as fresh as the wood we shape. One of the essential, timeless aspects of woodworking is understanding the different types of joints - the building blocks of woodworking. In this article, we explore the various types of joints and how they work. Plus, we have included a downloadable guide summarizing each type of joint, so you set it as your screensaver or bring it with you wherever you need it.

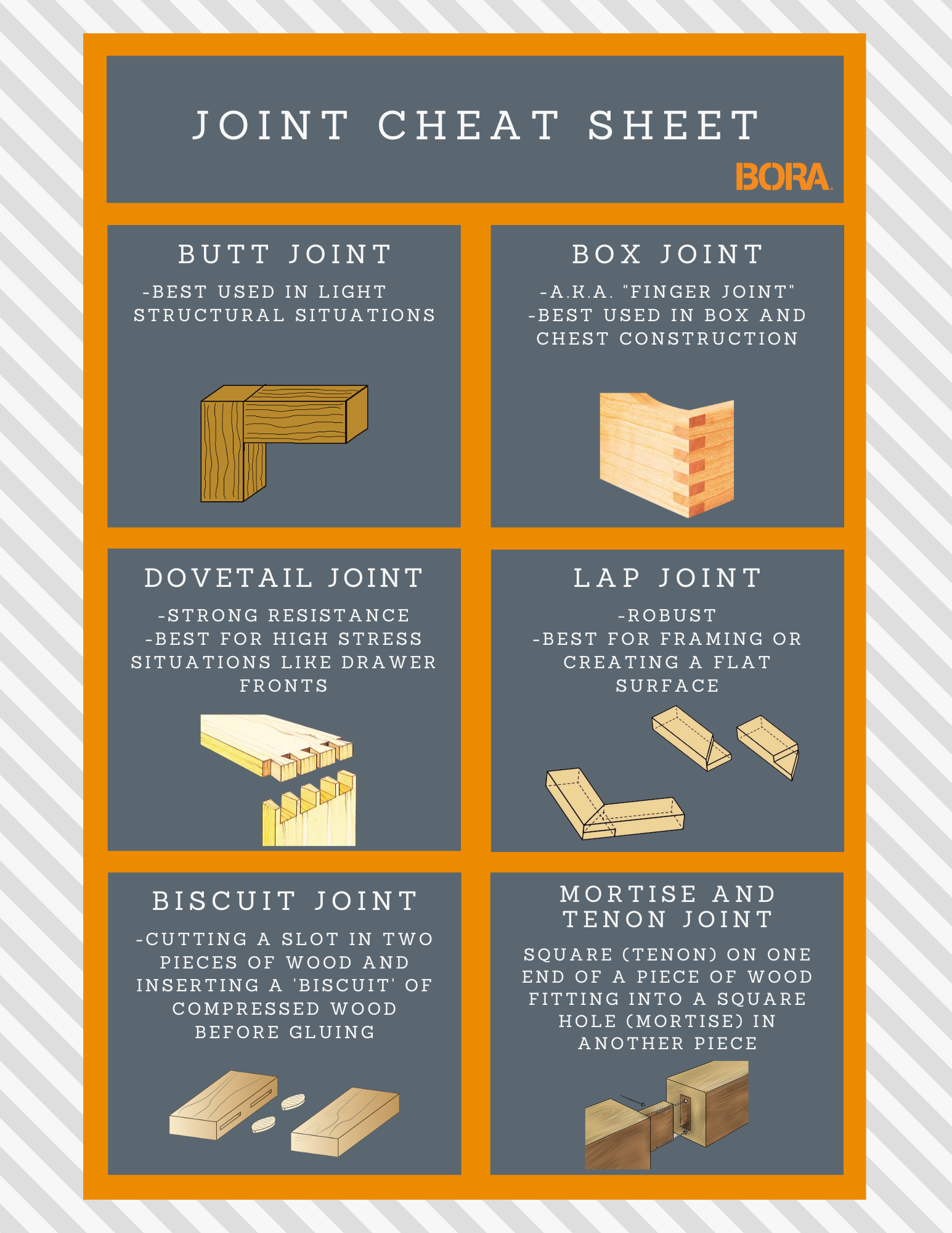

1. Butt Joint

The most straightforward type of wood joint is the butt joint. It usually involves connecting the end grain of one piece of wood to the long grain side of another, however, it can also be used like the biscuit joints without the biscuits. Despite its simplicity, the butt joint isn't the strongest; it's best used in light structural situations like framing or situations where you'll reinforce it with hardware.

2. Lap Joint

Lap joints are made by overlapping two pieces of wood. This joint is more robust than a butt joint due to the larger contact area for glue. It's often used in framing or when creating a flat surface with multiple pieces of wood.

3. Mortise and Tenon Joint

This joint involves a square (tenon) or rectangle on one end of a piece of wood fitting into a square hole (mortise) in another piece. It's one of the oldest types of joints and is known for its strength. It's used in many applications from furniture to house framing.

4. Dovetail Joint

The dovetail joint is known for its resistance to being pulled apart and its aesthetic appeal. The pins and tails of this joint interlock, making it ideal for high-stress situations, like drawer fronts. Dovetails are also self-squaring.

5. Box Joint

Also known as a finger joint, the box joint is similar to the dovetail but has square pins and slots. This joint is strong and aesthetically pleasing, and it's often used in box and chest construction.

6. Biscuit Joint

A biscuit joint involves cutting a slot in two pieces of wood and inserting a 'biscuit' of compressed wood before gluing. This joint is typically used for alignment purposes in edge-to-edge gluing.

Final Thoughts

Joints are the heart of any woodworking project, and the strength of a joint is not just in the connection itself, but also in how well it's held together during the bonding process. The type of joint you choose will largely depend on the project's demands. However, one constant is the need for a reliable clamping system.

When it comes to holding these joints in place during the glue setting process, the BORA parallel clamps are excellent tools to have in your workshop. It offers a large clamping surface that applies even pressure across the joint, regardless of its type, to ensure the glue sets correctly. The clamp's non-marring pads protect the surface of your wood while providing robust clamping pressure. In short, the BORA parallel clamp is your ultimate companion in achieving strong, secure joints.

Join us again as we continue to explore the timeless art of woodworking. Until then, keep shaping, joining, and creating. Happy woodworking!