The great debate rages on: which router should you buy? If you’ve spent any time in the shop, your answer is "Buy them all!" A router is arguably the most versatile power tool, with various sizes and options to suit a particular job or project. Below are some basic guidelines on what to look for, plus some key features that will extend the life of your router.

Fixed vs. Plunge base

The first hurdle is deciding to get a plunge router or a fixed base router. Again, the answer is YES — and depending on the job, you will need both at some stage. Rather than looking at it as having to choose one over the other, the best way to approach it is to buy the one that helps you finish the job you’re currently working on.

A fixed base, or barrel-style, router has the added option of being able to fit in a table more easily. When paired with a lift, you get a setup that can create molding and joinery quite easily. These types of routers adjust by turning inside a spiral that is machined in the base. This is manual, but it allows you to get an exact joinery cut so it fits flawlessly. The motor from a fixed base router can also be fitted to a CNC machine with the right fittings.

Plunge routers are great for making shapes in the middle of panels or doing accents such as fluting. They also come in handy if you are doing shelf pin holes. Plunge routers combine the base and the motor unit into one device. There are springs in the columns that allow the user to pull the motor unit downward. When this happens, the motor spindle and bits are moved downward toward the material. This is like how the mechanism of a drill press works but at much higher speed. It has adjustable stops, and there is a trigger positioned near one of the handles that releases and locks the spring mechanism. This means you can activate the spring release, plunge the bit into the material, and then lock the router at that depth. With the depth stop placed accurately, you can accurately replicate your work on multiple pieces.

Collets

Most router bits sold in North America have a 1/2” or 1/4” shank. Make sure your router comes with both. If you are buying a smaller router (sometimes called a trimmer), it will only come a 1/4” collet since this is used to do final finish work, round over edges, or create bevels. There are occasions when you will need other sized collets, but these are few and far between — so in the beginning stick to 1/2” or 1/4” and you’ll be fine.

Extras

There are a few bells and whistles that may also influence your decision. If you work with a variety of bit sizes, you are likely to want a variable speed router. Larger bits like raised panel bits need to be slowed down to 10,000 rpm, while smaller bits need the full speed of 20,000 plus.

Some routers also feature electronics inside them to deliver more power when the motor is under load. This means you maintain your bit speed and there is less chance of tear out or burning. When you start cutting you will hear the motor speed up. That is normal and a nice feature.

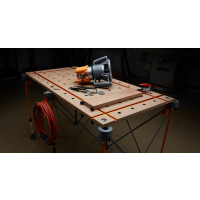

When it comes to routing, jigs and fixtures abound and there is a jig for just about any job you can imagine. Most of them are universal, to a point, and there are mounting points to accept most routers. These are commonly found online or at specialty woodworking retailers.

Bits and Pieces

Inevitably the question of router bits comes up in your research to buy a router. One theory says to buy them as you need them, but buy the best. Another camp says buy an economy set with a dozen bits, and replace them individually as needed with more expensive ones. Both are valid ways to tackle the problem.

What I would say is do your research. Not all bits are created the same, and a significant amount of science goes into creating a bit that cuts the way it should. During one project, I was using a well-known brand and realized that actual shavings were being produced. Long streams of wood were being sliced from the workpiece. At that point I was so happy that I had a quality bit doing the job and I would now be reluctant to buy a one-off cheapie unless I truly knew I was unlikely to use it again. It is completely up to your preferences and budget, but choose wisely since your results are directly related to the bit spinning in that motor.

Routers are by all accounts the most universally used power tool. Do some research and start with one that fits the bill in terms of power, flexibility, and reliability. You won't be sorry, and your woodwork will take on some new accents and accuracy.

Want to stay up-to-date on BORA® products, announcements, and tips? Sign up for our newsletter for all the latest!